The Torch Cap fault Light Emitting Diode (LED) illuminates when the

torch or Hypertherm® cartridge is not ready to cut or is not able to cut.

Fault codes and fault LEDs

| Fault code |

Fault LEDs |

Torch LED |

Description |

Stops the system from operating? |

| None |

ON

|

Yellow

|

The Hypertherm cartridge was off, the torch was disconnected, or the

torch was in the yellow lock (X) position during a

restart. |

Yes |

Corrective action for the Hypertherm cartridge and torch

-

Move the torch-lock switch to the green "ready to fire" position.

This fault can show when you do a restart while the torch-lock switch

is in the yellow lock (X) position.

-

Remove the Hypertherm cartridge, and reinstall it correctly.

-

Reconnect the torch to the plasma power supply, and do a quick

restart.

- Optional::

Machine torch: Lock and unlock the torch, or do a quick restart.

This fault can be caused by removing the Hypertherm cartridge without first

setting the torch-lock switch to the yellow lock position or setting

the power switch to OFF (O).

- Optional::

Mini machine torch: Do a quick restart.

This fault can be caused by removing the Hypertherm cartridge without first

setting the power switch to OFF (O).

-

If possible, do a test with a different torch that is known to work

correctly.

-

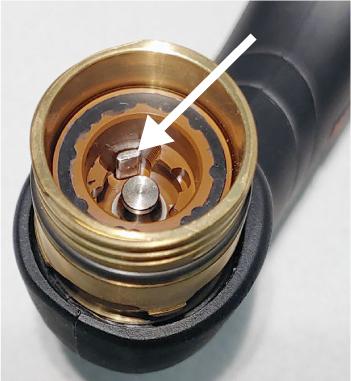

Push down the plunger in the torch head and then release.

-

Does the plunger move freely and go back to its start position?

OptionDescription

| If yes... |

Continue with the next procedure. |

| If no... |

Replace the torch body. |

Corrective action for the torch cap sensor in the torch and torch

lead

-

Disconnect the torch from the plasma power supply.

-

Make sure that a Hypertherm

cartridge is correctly installed on the torch and is not too loose or

too tight.

-

Make sure that the torch is set to the green "ready to fire"

position.

-

Measure the resistance between pin 5 and pin 7 in the torch

connector.

-

Is the resistance very low?

OptionDescription

| If yes... |

Continue with the next step. |

| If no... |

The cap-sensor switch in the torch is open. Continue with

step 9. |

-

Set the torch to the yellow lock (X) position.

-

Measure the resistance between pin 5 and pin 7 in the torch connector

again.

-

Is the resistance open?

-

Do a check for continuity on the torch wires:

-

Remove the left side of the torch shell.

-

Do a check for continuity between the blue wire and pin 5 (BLU)

in the torch connector.

-

Do a check for continuity between the orange wire and pin 7

(ORG) in the torch connector.

-

Do both torch wires have continuity?

OptionDescription

| If yes... |

Replace the cap-sensor switch. |

| If no... |

Replace the torch lead. |

Corrective action for the torch cap sensor in the plasma power supply

-

Set

the power switch to OFF (O), and disconnect the power cord from the power

source.

-

Remove the plasma

power supply handle and cover.

-

Remove the

component barrier.

-

Do a check for continuity on the torch receptacle.

-

Does each torch receptacle wire have continuity?

OptionDescription

| If yes... |

Continue with the next step. |

| If no... |

Replace the torch receptacle. |

-

Reconnect the torch to the plasma power supply.

-

Make sure that the Hypertherm

cartridge is installed correctly on the torch.

-

Make sure that the torch is set to the green "ready to fire"

position.

-

Measure the resistance between pin 1 and pin 2 at J19 on the power

Printed Circuit Board (PCB).

-

Is the resistance very low, approximately 1 ohm (Ω) or less?

OptionDescription

| If yes... |

If you cannot find or

correct the problem, a qualified service technician must repair the system. Speak to your

distributor or authorized repair facility. |

| If no... |

The cap-sensor switch circuit is open. Replace the power

PCB. |